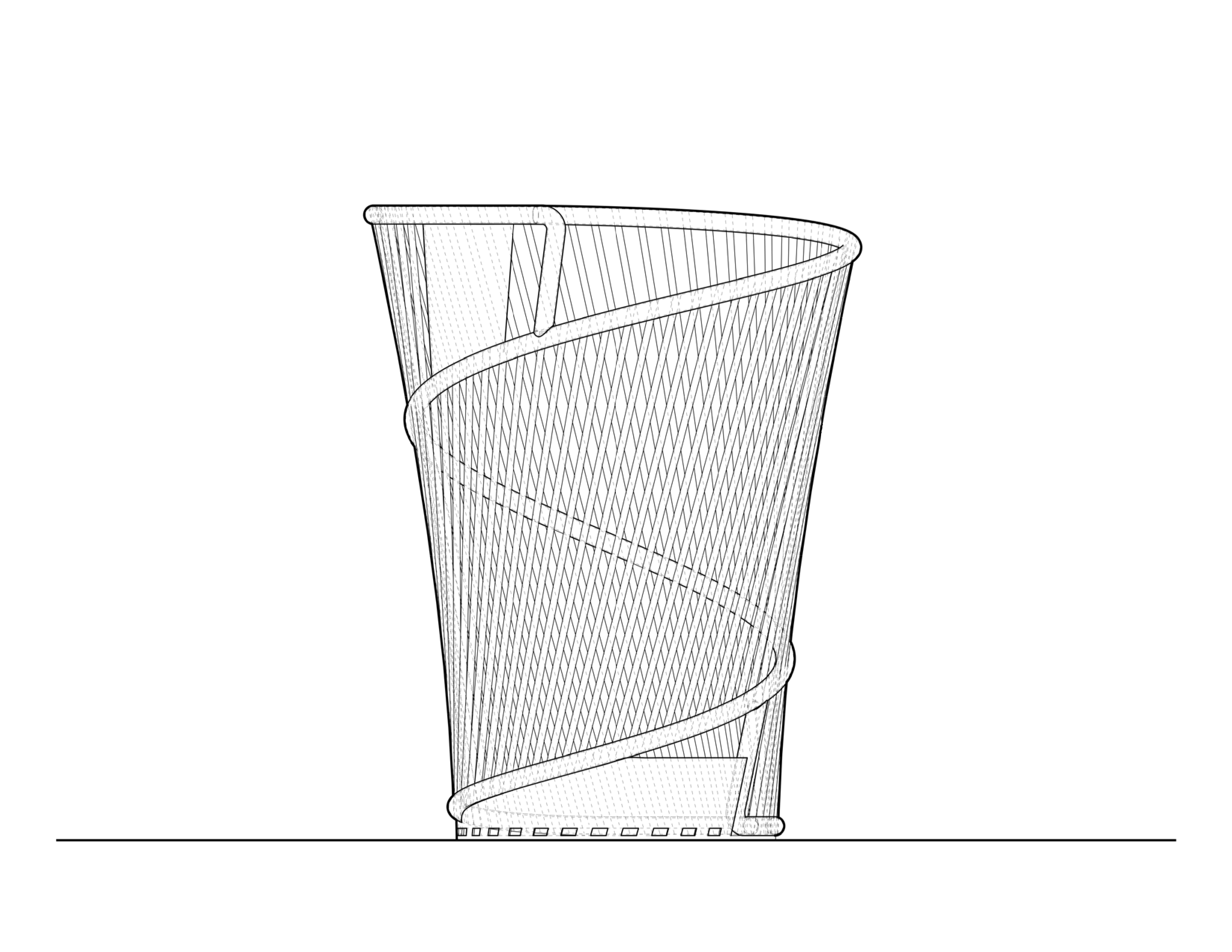

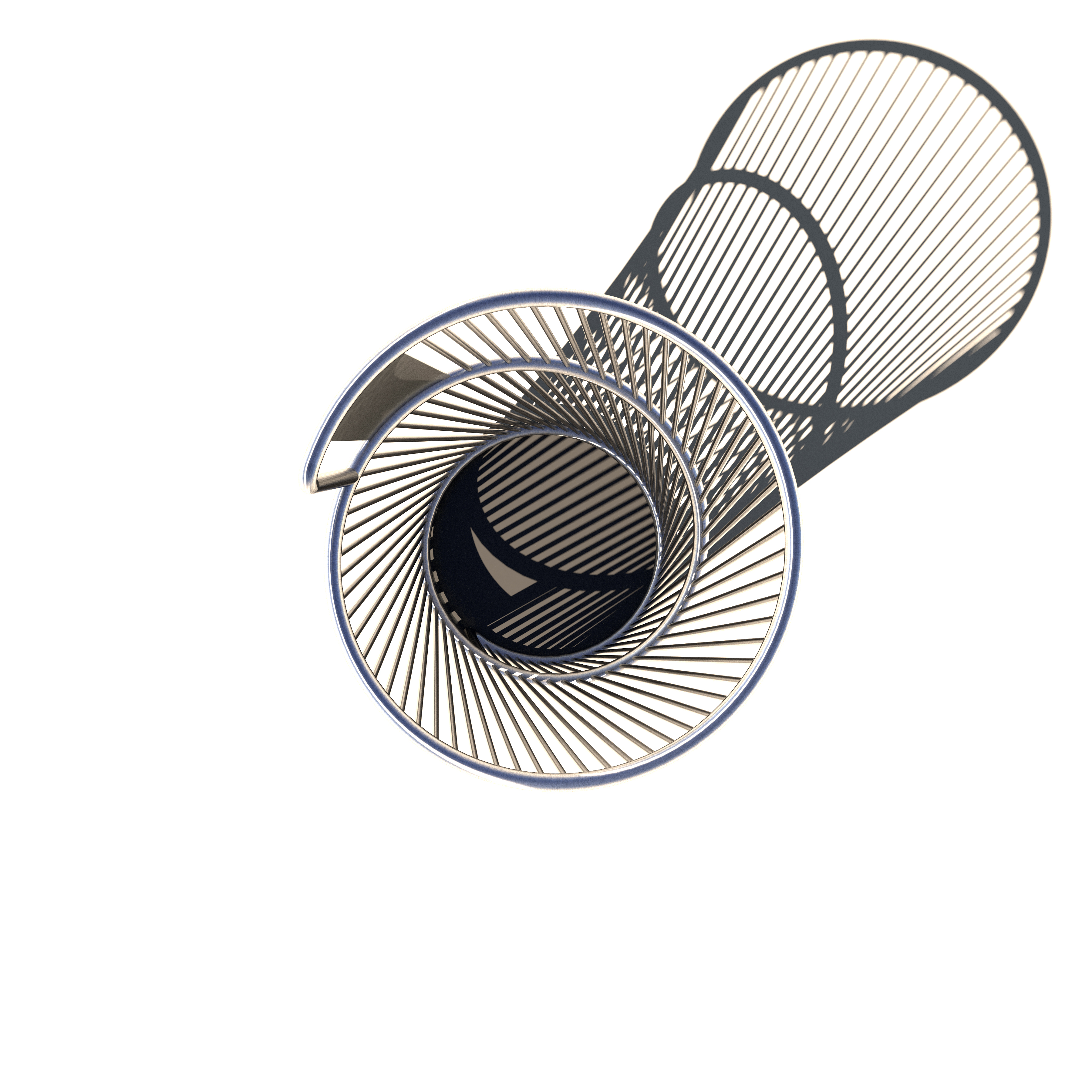

This entry to the 2018 BetterBin competition by the NYC Department of Sanitation and the Valen Alen Institute presented a unique shape that’s clean, contemporary and instantly recognizable. Like New Yorkers, it’s tough. It’s forward thinking. Materially, it’s simple. Stainless steel tubing is as home on NYC subway stairs as it is at MoMA. The hyperboloid shape keeps the connecting rods straight. Its mathematically driven form is a distinguished, modern update on the steel and mesh design New Yorkers have known for eighty years.

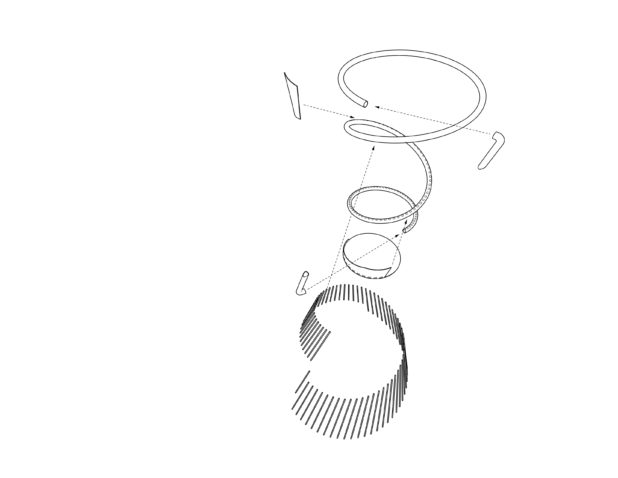

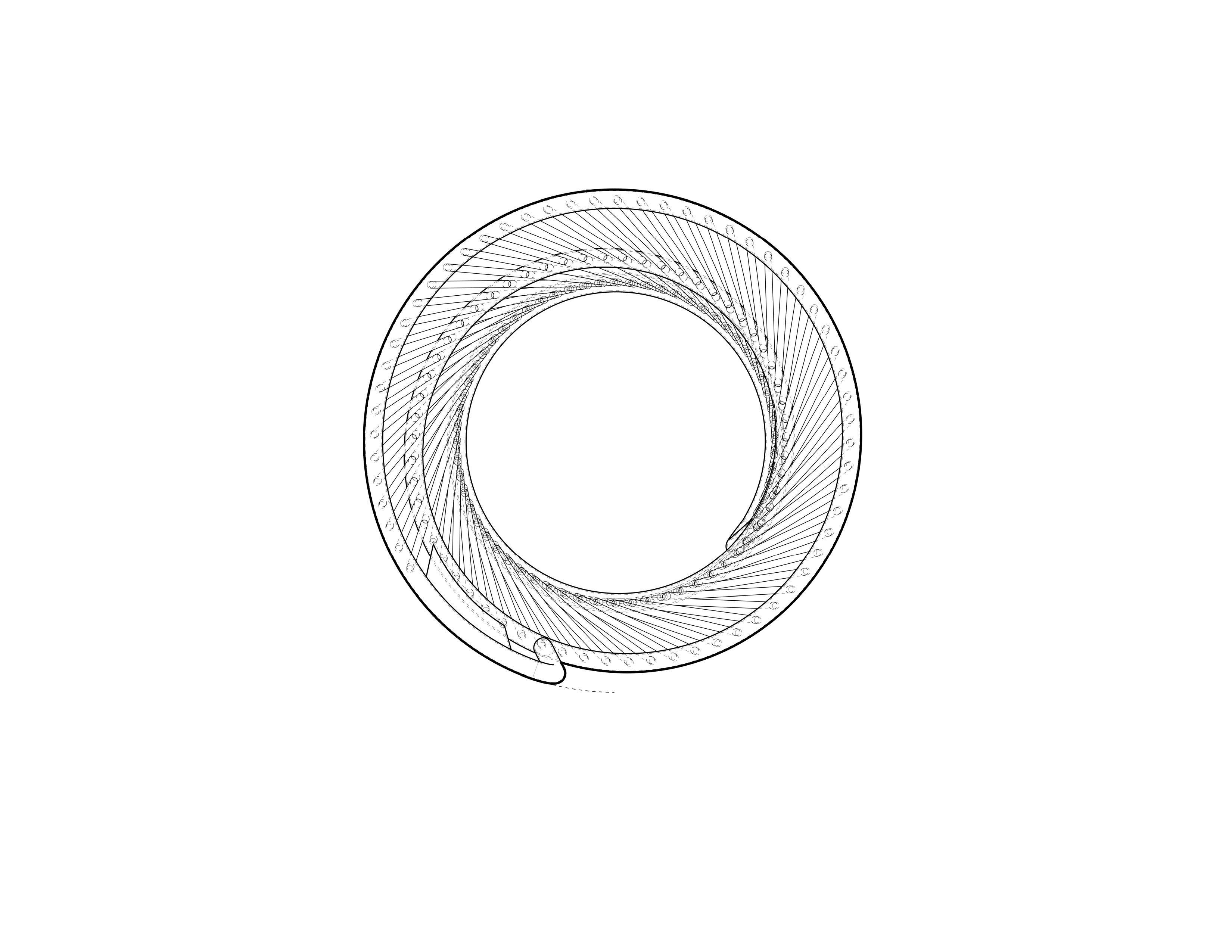

The Gotham Whorl uses standard materials in new ways. The helical spine is CNC bent and holes are created using a five-axis laser cutter. The tube is a sophisticated component, but the precision afforded by computer-controlled fabrication allows the rest of the assembly to go together like a kit of parts. The exact location for the messaging plate and the curling part of the base plate—both ruled surfaces—will be determined by notches in the pipe. Welds will be added only where necessary, saving on fabrication cost. Where the straight rods pass through the tube, no welds are needed. An extremely clean detail. Likewise, at the top of the basket, where users will come into contact with the metal, there are no welds.

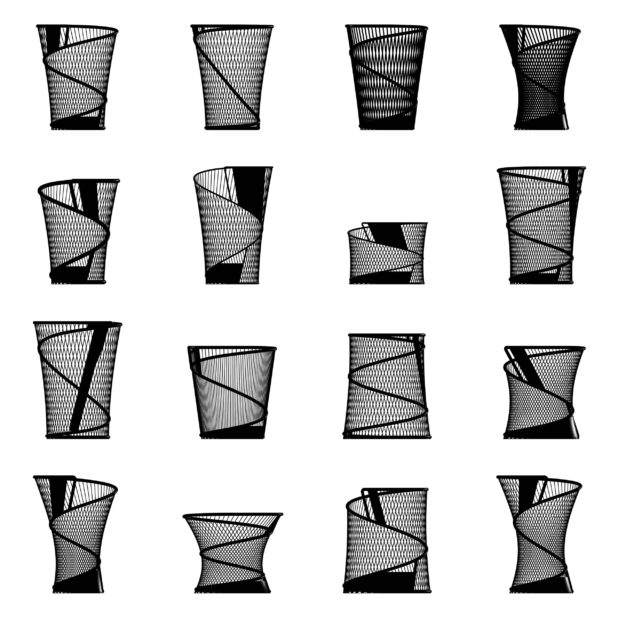

Inspired by an ongoing exploration into the relationship between form and fabrication techniques, the design was created using a sophisticated, mathmatically-driven process. Form is the result of fundamental geometric relationships (the top and bottom diameters, the overall height, the “twistiness” of the rods). These driving inputs are linked together in a parametric model, allowing for detailed integration of fabrication and functional constraints. 3D-printed physical models were generated at regular intervals to test assumptions such as the way the individual baskets nest when stacked.

The Gotham Whorl is versatile. The standard basket can be easily converted into recycling receptacle by attaching a simple concave lid to the bent tube frame. Where necessessary, this type of modification can also be used to discourage illegal dumping of household trash. Furthermore, the parametric relationships that generated this design could be endlessly adapted in the future to create receptacles meeting a wide range of requirements.